- Home

- >

- Products

- >

- L Shape Door Frame Edge Banding Machine

- >

- European L Shape Door Frame Pre Milling and Corner Trimming Edge Banding Machine

European L Shape Door Frame Pre Milling and Corner Trimming Edge Banding Machine

Brand :Baoshan

Product origin :China

Delivery time :15 days after received payment

Supply capacity :100 sets/ month

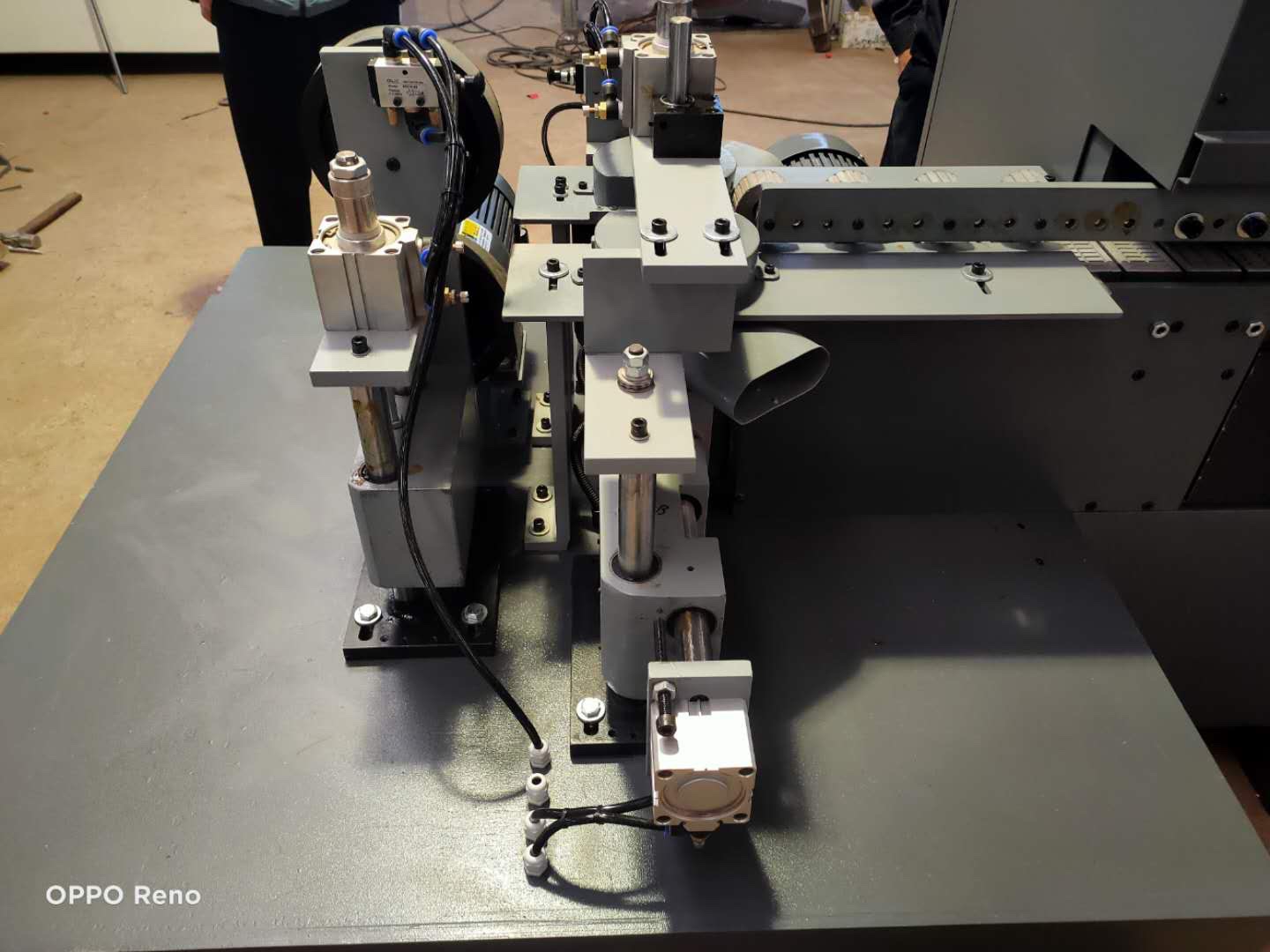

Our MF1504AFG PRO European L Shape Door Frame Pre Milling and Corner Trimming Edge Banding Machine has functions such as automatic feeding, milling, gluing, edge banding, and corner trimming It is an integrated door line edge banding and modeling machine. Only one worker is needed for operation.

We are one of a few factories in China which can produce door line edge banding machines with modeling function and our modeling function skill is one of the most mature ones.

We have partners all over the world among which are some famous dealers such as KAMI in Russia.

Product name

European L Shape Door Frame Pre Milling and Corner Trimming Edge Banding Machine

Features:

MF-1504AFG PRO is applicable for the linear plane edge banding of medium density fiberboard(MDF),flake board, cabinetwork board, soiled Wood board and etc. The materials of the edge can be ABS, PVC, wood veneer, wood strip or melamine.

Flexible, advantages of high performance, easy debugging, convenient in maintenance and easy to operate

High quality electric components and transmitting make machine faction steadier.

Full-close safety shield, more human operation.

efficiency and labor saving:

MF-1504AFG (Pro)is our high speed door line edge banding machine. The feed speed can reach 35 meters/min.

35 meters=8 pieces work piece

8 pieces*60mins=480 pieces /hour

480*8 hours/day=3840 pieces /day=16800 meters per day

big edge band height:

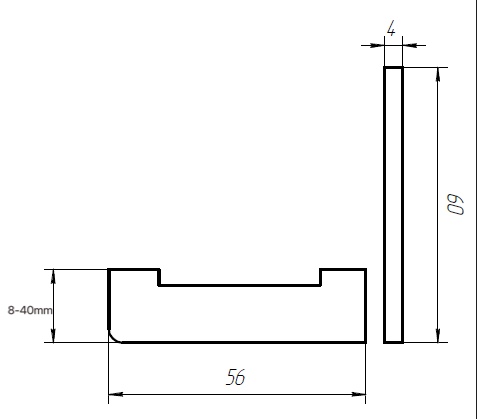

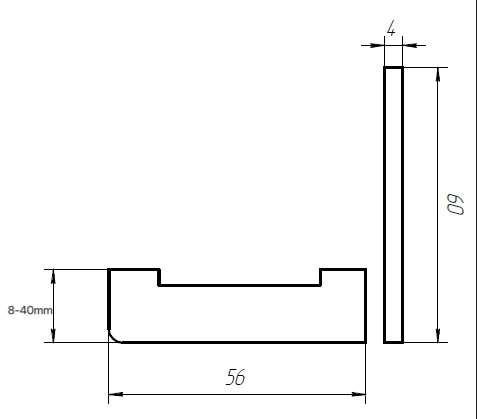

This machine is special because the height of the band goes up to 60mm while other machines only go up to 40mm.

60mm high bands are very common in Russia and some other European countries.Customers have a difficulty finding

machine does this

small work piece thickness requirment:

MF1504AFG Pro is equipped with pre-milling knife and the requirement for the thickness of the work piece is as low as 8mm-40mm compared to the common 12-40mm which is very important for most clients in Europe.

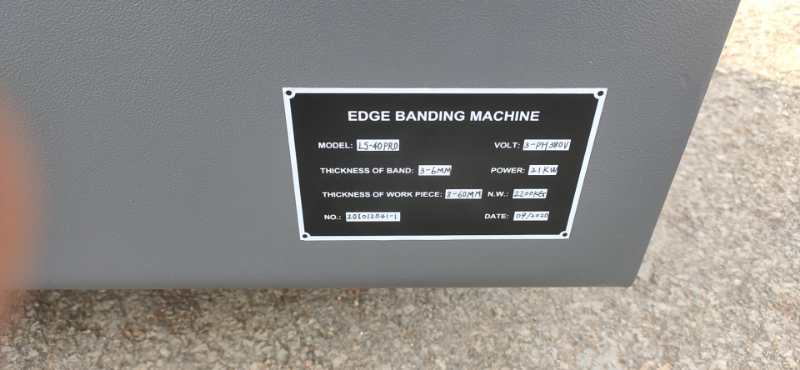

Parameters

Product name | Mode | Parameters | Work process |

Automatic door line edge banding machine | MF1504AFG PRO | Weight of the machine: 1500 Kg Working power: 3-HP_380V Total power: 21Kw Thickness of edge band: 3-6mm Thickness of work piece: 8-40mm Min. Width of work piece: 65mm Feed speed: 12-20m/min Height of edge band: 60mm Work piece interval: 3s-5s Air pressure: 0.5-0.8Mpa Overall dimension(L*W*H): 3700*1120*1900mm | Send board—milling mouth 1 —milling mouth 2 —gluing—edge banding—corner trimming both sides |

Function of edge banding machine

MF-1504AFG PRO is an automatic edge banding machine, which is used to woodworking edge banding. Special for door line edge banding.

The main function as followed:

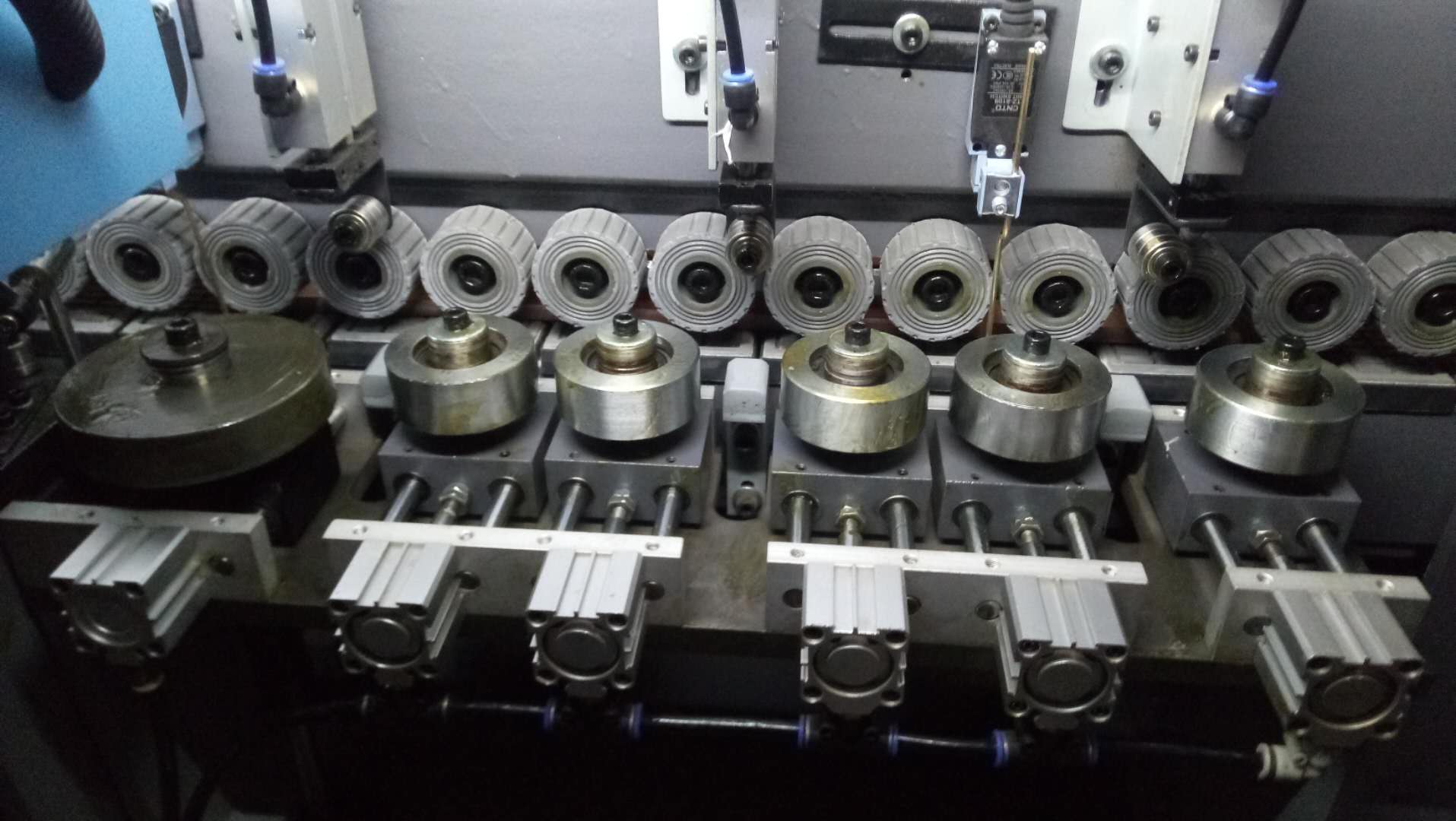

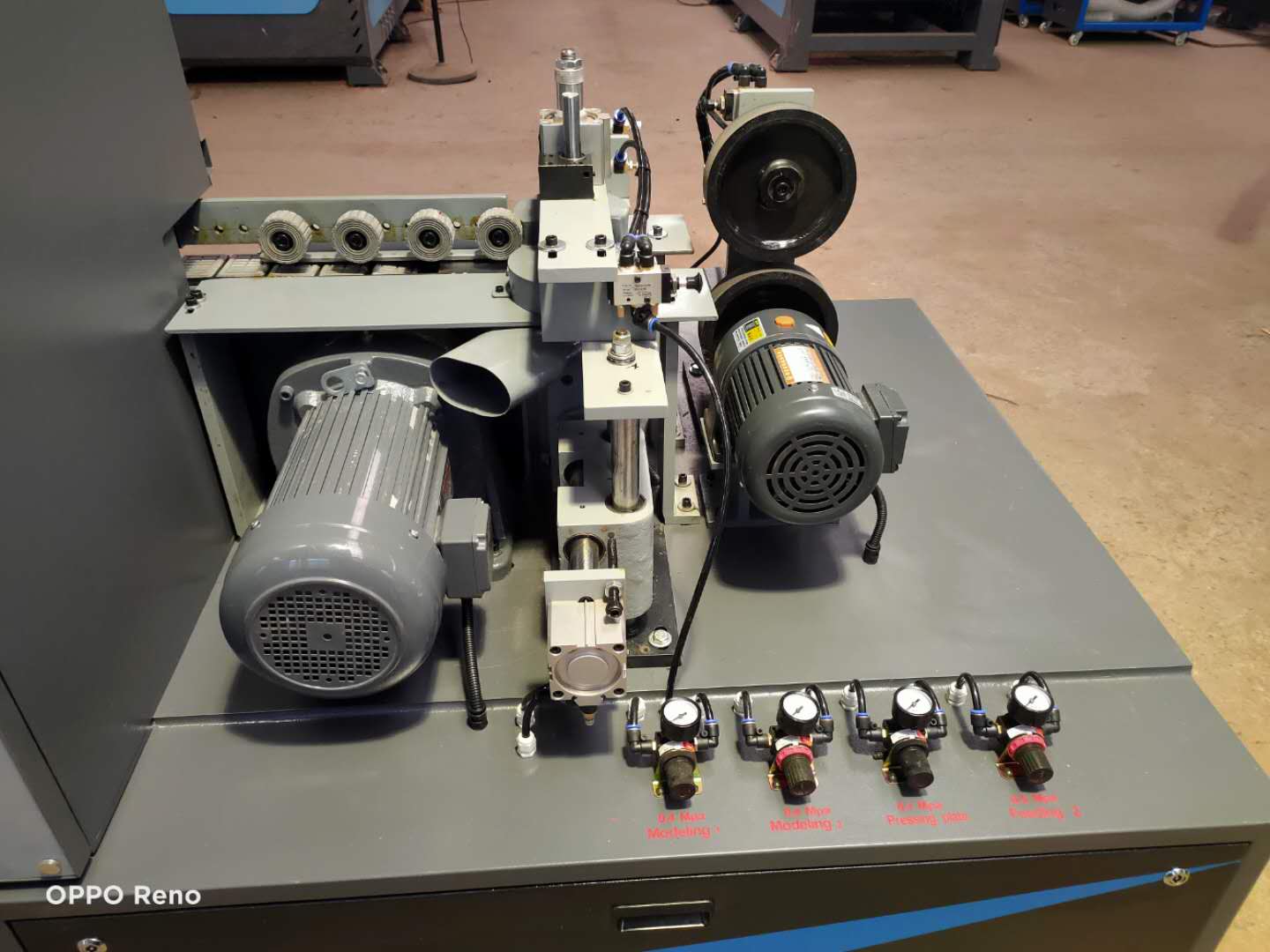

Send board—milling mouth 1 —milling mouth 2 —gluing—edge banding—corner trimming both sides

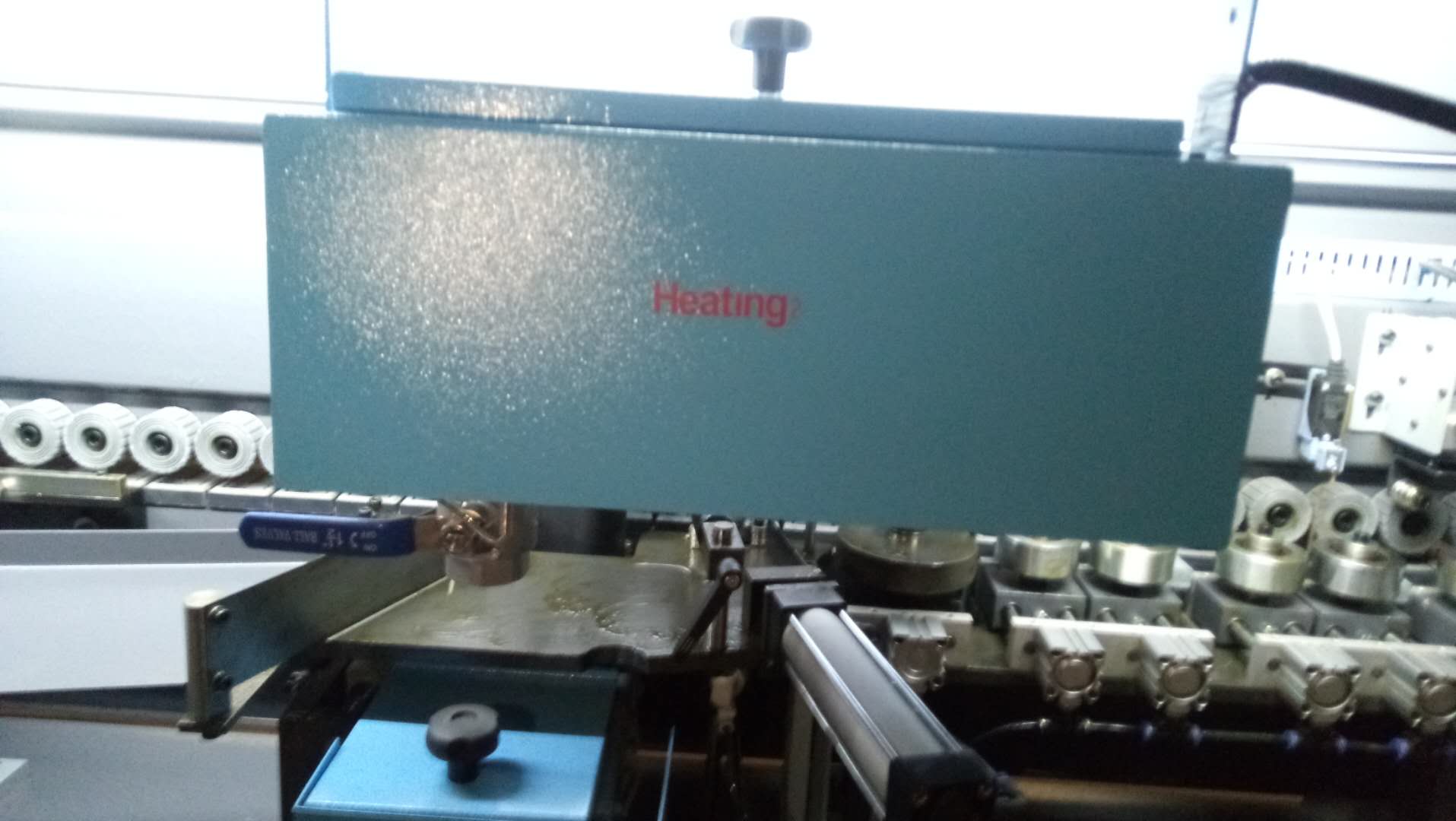

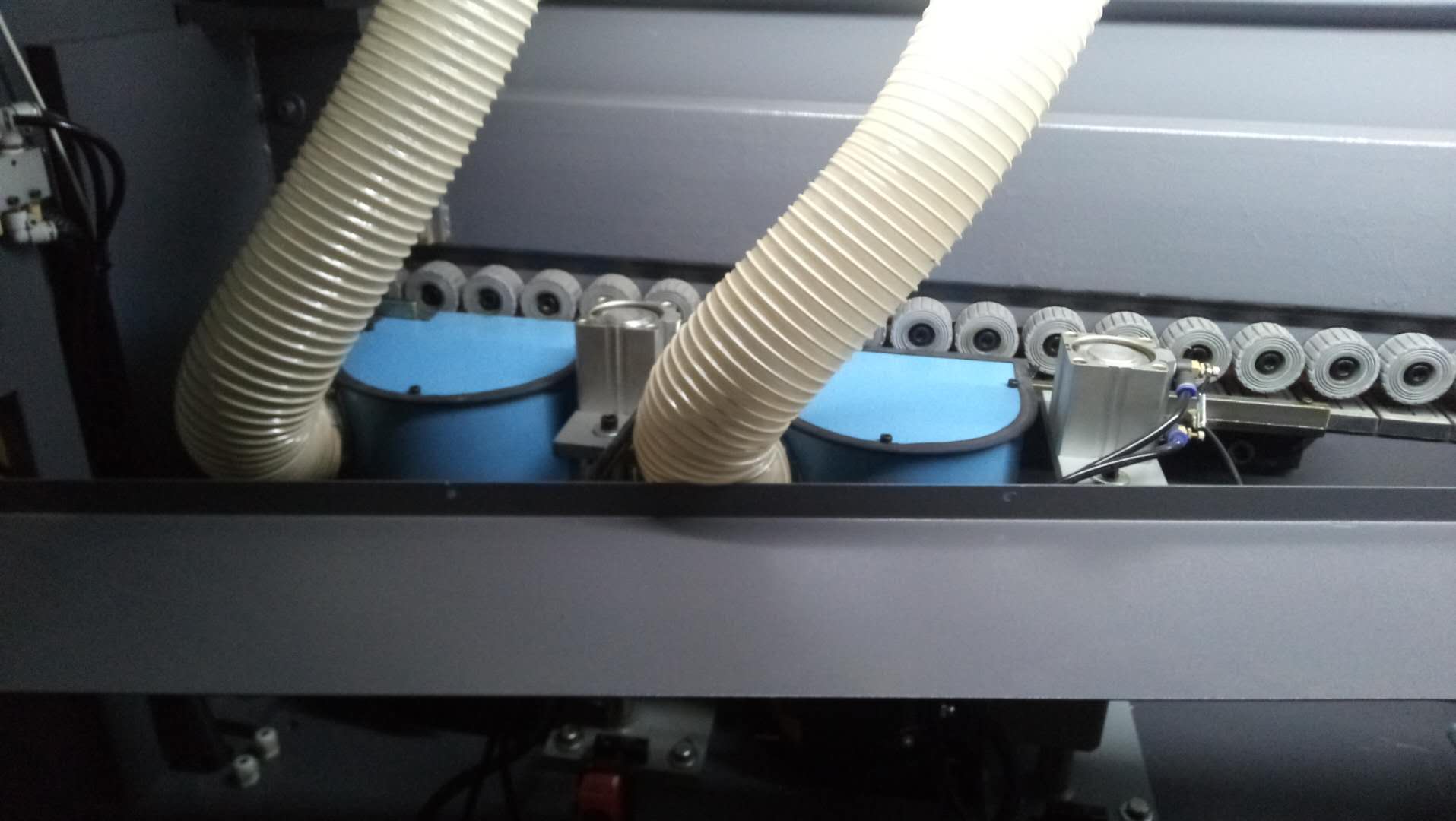

Detail pictures:

This door frame edge banding machine processes the work piece with a height of 60mm compared to the common size in the market 40mm. It is popular in Russia and other ajacent countries where big height work piece is common.

Parts

PLC touch screen: pre-input system.Easy to operate.

Manual instruction provided.

Big glue boxes: 1 big and 1 small with big volumn.

Automatic working system: only need one worker to operate with each machine.

Hot melt adhesive: we use high temperture hot melt adhesive(glue) with lower cost and applicable for most of work enviroment.

Why choose us

Professional technical staff:

Baoshan woodworking equipment factory has been woodworking machine suppliers and producer more than 20 years, there have some technical staffs doing woodworking machine produce since factory established.we actively strengthen the international communication and sent employees to study abroad in Europe, USA and Taiwan.

OEM&ODM service

Origin entrusted manufacture & origin design manufacture

Strict quality control

Our engineer and workers have more than 20 years experience. We can control the quality well.

Fast delivery

We have ability and rights to export the machines and control all step of exporting well.

Good after-sales service

Engineers are available to service at overseas.

Resource advantage

equipment production base center in our country. The workshop covers an area of 20000sq.m, among which the construction area is about 8000sq.m.

Services

Reply customer inquiry within 24 hours

10 years Golden supplier continuously on Alibaba. More than 20 years industry technology experience

Offer spare parts and service within 12 months warranty for FREE

After sale team will answer all your questions about the sold machine for life long.

Technology support provide operation VIDEO for training

Field repairment if required

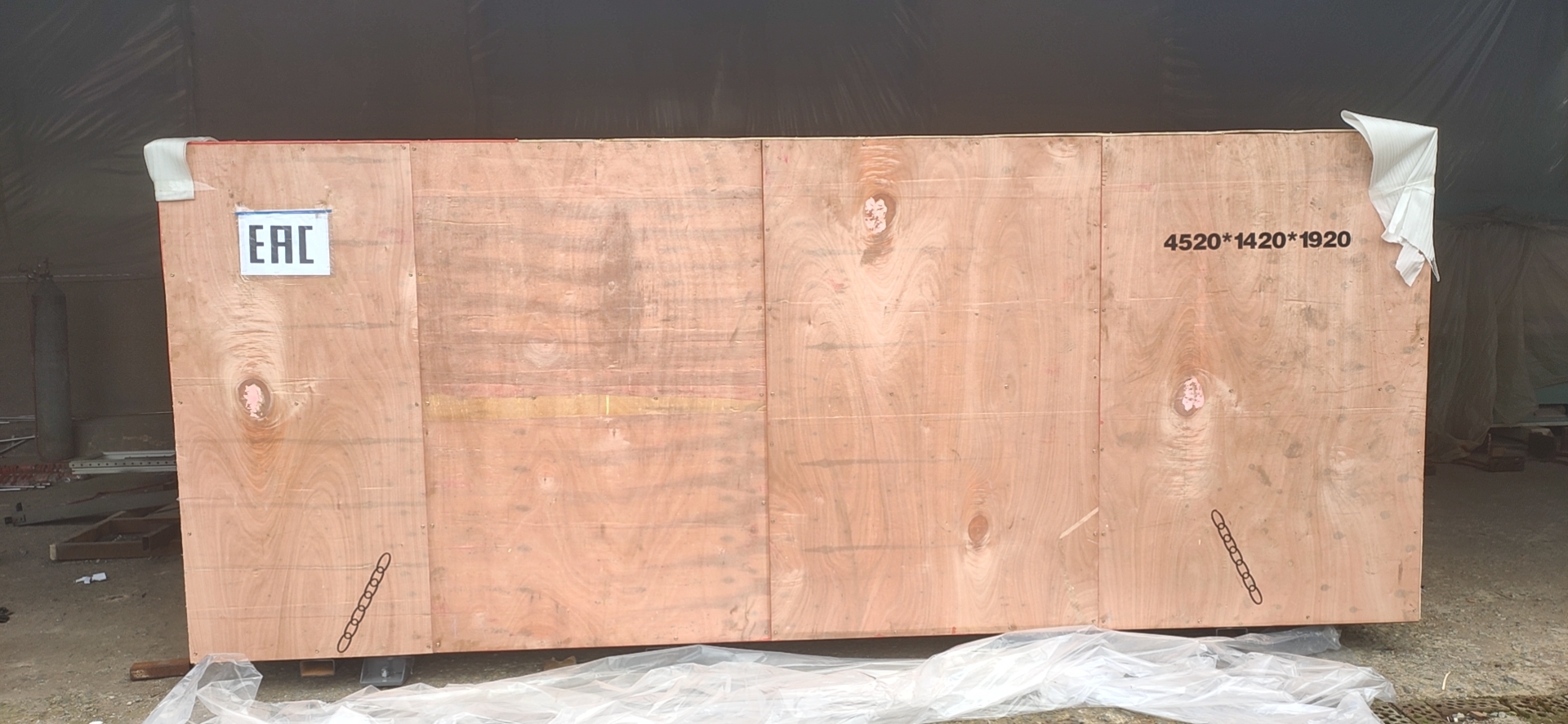

Packaging & delivery

Packaging details: wooden box with foam packaging

Delivery time: about 25 days or 4 days if in stock.

We choose the professional wooden packaging company ensure that all machine packed well.

Contact information

Email: vivienjin007@hotmail.com

Phone No.: 0086-17642056231

Fax: 0086-024-89592706

Add: Shenyang city Sujiatun District Tonggou Town Ligou Village Shenyang Liaoning Province China (Mainland)